Fully Automatic Paint Spray Booths / Setups

We are Authorised Dealer, Distributor, Supplier of Fully Automatic Paint Spray Booths / Setups (For All Over India). Also, we are a Manufacturer, Supplier, Exporter of Zinc (Zn), Aluminium (Al) Flake Coating Plants. Our setup is situated in Pune, Maharashtra, India.

Semi Auto Single tank Dip Spin Machine

- Spin RPM – 25 to 500 RPM

- Basket Size – 450/600 MM

- Parts Loading by manually

- Basket Loading Capacity – 50 to 60 kg

- Automatic control with dedicated programs for different parts.

- Tilting facility for socket head fasteners.

- 600 – 800 kg Per Hrs production Capacity

- coating parts unloading directly on linked conveyor to oven conveyor by top opening basket actuated

Our Products / Services

Manual Zinc Al Flake Coating Plant

A proper method for coating parts with wide surface area or parts where appearances area deemed important.

Discover the power of Zinc Al Flake Coating Spray Setup for unparalleled corrosion resistance. Learn about the innovative spray process, its advantages, and why it's the ultimate choice for robust coating solutions.

In the realm of corrosion protection, the Zinc Al Flake Coating Spray Setup stands as a revolutionary approach to fortify metal surfaces against the relentless effects of corrosion. By combining the strengths of zinc and aluminium, this advanced process creates a resilient shield that outperforms traditional coatings. This article delves into the intricacies of the Zinc Al Flake Coating Spray Setup, explaining its application, benefits, and why it is the preferred solution for industries seeking top-tier durability and protection.

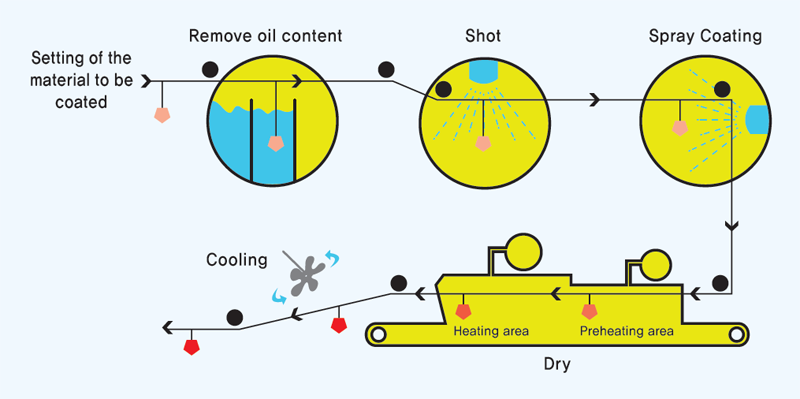

Central to the Zinc Al Flake Coating Spray Setup is an innovative process that ensures a uniform and impenetrable layer of defense. During this procedure, a specially formulated mixture of zinc and aluminium flakes is sprayed onto metal components. The coating bonds seamlessly to the surface, creating a robust barrier that shields against corrosive elements.

- Unrivaled Corrosion Resistance :

- Even and Consistent Application :

- Versatility in Application :

- Eco-Friendly Solution :

- Enhanced Durability :

- Long-Term Cost Savings :

The Zinc Al Flake Coating Spray Setup provides exceptional defense against corrosion, significantly prolonging the lifespan of metal parts even in challenging environments.

The spray setup ensures a uniform coating thickness, eliminating weak spots and vulnerabilities that are common with traditional coatings.

From intricate pieces to large structures, the Zinc Al Flake Coating Spray Setup can be customized to suit various shapes and sizes, making it a versatile choice for a multitude of industries.

Many spray setups use environmentally friendly water-based solutions, reducing harmful emissions and minimizing the ecological impact compared to other coating methods.

The combination of zinc and aluminium offers outstanding resistance to abrasion, ensuring your coated components can endure rigorous usage.

The Zinc Al Flake Coating Spray Setup is a cost-effective investment due to its extensive protection and prolonged lifespan, reducing maintenance and replacement costs over time.

At Cotech Finishers Pvt.Ltd., we lead the industry in providing cutting-edge coating solutions, including the Zinc Al Flake Coating Spray Setup. With years of expertise and a commitment to innovation, we deliver unparalleled quality and service. Our advanced facilities and skilled technicians guarantee that your components receive top-notch protection through this state-of-the-art spray process.

When it comes to shielding your valuable metal components from the persistent threat of corrosion, the Zinc Al Flake Coating Spray Setup emerges as a top-tier choice. Its exceptional corrosion resistance, consistent application, versatility, and environmental advantages make it an irresistible solution for industries seeking ultimate durability and performance. Contact us at Cotech Finishers Pvt.Ltd. to explore how the Zinc Al Flake Coating Spray Setup can revolutionize your coating requirements, ensuring your products remain resilient and dependable over the long haul.