Fully Automatic, Semi Automatic, Manual Dip Spin Machines

We are Manufacturer, Supplier, Exporter of Fully Automatic Dip Spin Machines, Semi Automatic Dip Spin Machines, Manual Dip Spin Machines for products like Zinc (Zn), Aluminium (Al) Flake Coating Chemicals (For Worldwide). Also, we are Manufacturer, Supplier, Exporter of Zinc (Zn), Aluminium (Al) Flake Coating Plants. Our setup is situated in Pune, Maharashtra, India.

Manual Zinc AL Flake coating Machine

- Spin RPM – 25 to 500 RPM

- Basket Size – 450 MM

- Basket Loading Capacity - 25 to 35 kg

- Automatic control with dedicated programs for different parts.

- Tilting facility for socket head fasteners.

- 400 – 500 kg Per Hrs production Capacity

Our Products / Services

Semi Auto Single tank Dip Spin Machine

- Spin RPM – 25 to 500 RPM

- Basket Size – 450/600 MM

- Parts Loading by manually

- Basket Loading Capacity – 50 to 60 kg

- Automatic control with dedicated programs for different parts.

- Tilting facility for socket head fasteners.

- 600 – 800 kg Per Hrs production Capacity

- coating parts unloading directly on linked conveyor to oven conveyor by top opening basket actuated

Fully Auto Dip Spin Machine

- Spin RPM – 25 to 500 RPM

- Basket Size – 450/600 MM

- Parts Loading Auto by loader.

- Basket Loading Capacity – 50 to 60 kg

- Basket Loading Capacity – 50 to 70 kg

- Automatic control with dedicated programs for different parts.

- Tilting facility ( 60 Degree) for socket head fasteners.

- 800 – 1000 kg Per Hrs production Capacity

- coating parts auto unloading directly on linked conveyor to oven conveyor by top opening basket actuated

- Auto weight system by loaded parts .

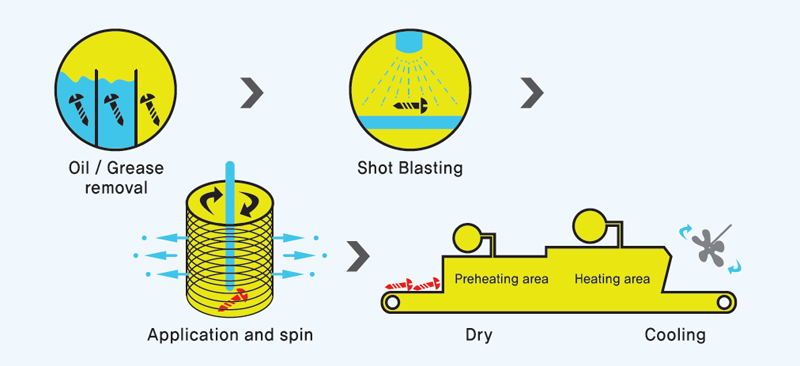

A method appropriate for coating small articles such as bolts, nuts, clips, etc.

Explore the benefits of a cutting-edge Zinc Al Flake Coating Dip Spin Setup for unmatched corrosion protection. Learn how this innovative process works and why it's the ultimate solution for your coating needs.

When it comes to safeguarding metal surfaces against the relentless forces of corrosion, the Zinc Al Flake Coating Dip Spin Setup stands out as a game-changing solution. This advanced process combines the strength of zinc and aluminium to create a robust protective layer that outperforms traditional coatings. In this article, we delve into the intricacies of the Zinc Al Flake Coating Dip Spin Setup, explaining how it works and why it's a crucial choice for industries seeking unmatched durability and resilience.

At the heart of the Zinc Al Flake Coating Dip Spin Setup lies a revolutionary process that ensures a uniform and impenetrable layer of protection. During this procedure, metal components are immersed in a specialized solution containing zinc and aluminium flakes. The carefully formulated mixture adheres to the surface, forming a tightly bonded coating that acts as a shield against corrosive elements.

- Superior Corrosion Resistance :

- Uniform Coverage :

- Highly Adaptable :

- Environmentally Friendly :

- Enhanced Durability :

- Cost-Effective :

The Zinc Al Flake Coating Dip Spin Setup provides exceptional corrosion protection, extending the lifespan of metal components even in harsh environments.

The dip spin process ensures an even and consistent coating thickness, eliminating weak points and vulnerabilities that are often present in traditional coatings.

From intricate parts to large structures, the Zinc Al Flake Coating Dip Spin Setup can be tailored to suit a wide range of sizes and shapes, making it a versatile choice for various industries.

This setup often utilizes water-based solutions, minimizing harmful emissions and reducing the ecological footprint compared to other coating methods.

The combination of zinc and aluminium offers exceptional durability and scratch resistance, ensuring your coated components can withstand wear and tear.

With its comprehensive protection and prolonged lifespan, the Zinc Al Flake Coating Dip Spin Setup proves to be a cost-effective investment in the long run, reducing maintenance and replacement expenses.

At Cotech Finishers Pvt.Ltd. , we are industry leaders in providing cutting-edge coating solutions, including the Zinc Al Flake Coating Dip Spin Setup. With years of experience and a commitment to innovation, we deliver unmatched expertise and quality. Our state-of-the-art facilities and expert technicians ensure that your components receive the highest level of protection through this advanced coating process.

When it comes to safeguarding your valuable metal components against the relentless threats of corrosion, the Zinc Al Flake Coating Dip Spin Setup stands as an unrivaled choice. Its exceptional corrosion resistance, uniform coverage, adaptability, and environmental benefits make it a compelling solution for industries seeking the utmost protection and longevity. Contact us at Cotech Finishers Pvt.Ltd. to discover how the Zinc Al Flake Coating Dip Spin Setup can revolutionize your coating needs and elevate your products to a new level of durability and performance.